Advanced Automation for Bottle Handling Efficiency #

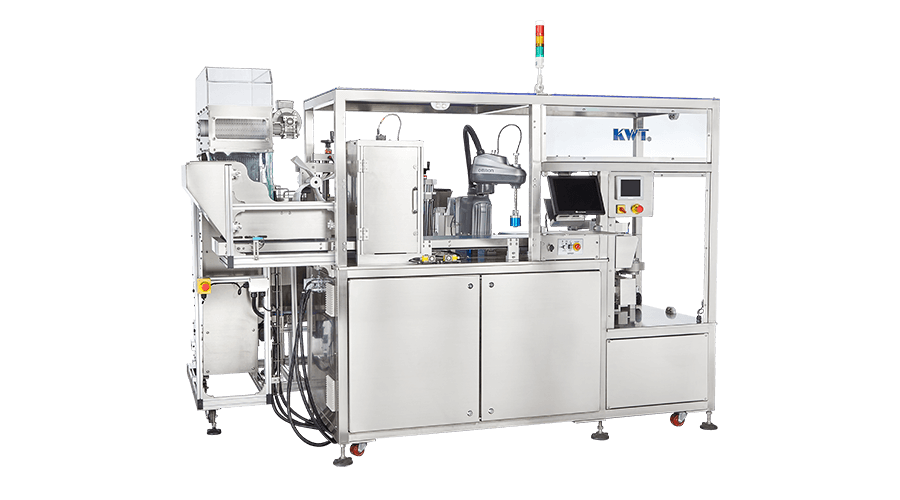

Explore the innovative features and benefits of the KWT Robotic Bottle Unscrambler, a solution engineered to streamline bottle handling processes in modern manufacturing environments. This system integrates advanced robotics, vision positioning, and adaptable tooling to address the evolving needs of automated production lines.

Product Overview #

The KWT Robotic Bottle Unscrambler is designed to optimize production efficiency and reduce manual labor costs. By incorporating state-of-the-art robotics and automation, this solution enhances the versatility and reliability of bottle handling operations.

Key Features #

- Vision-Guided Robotics: Utilizes a vision system for precise positioning and orientation of bottles, minimizing handling errors.

- Versatile Handling: Capable of accommodating various bottle shapes, sizes, and packaging configurations, supporting diverse production requirements.

- Seamless Integration: Easily integrates with existing production lines and collaborates with other machinery for a cohesive manufacturing process.

- Adaptability: The system can be reprogrammed or adjusted to handle different bottle types or production needs, offering flexibility for changing demands.

- Labor Optimization: Automation reduces the need for manual intervention, leading to significant labor cost savings and allowing staff to focus on more complex tasks.

System Components #

- Cap hopper feeds products to the belt conveyor

- Robotic arm equipped with a vision system for pick-and-place operations

- Containers are loaded onto a hugger belt for further processing

Technical Specifications #

- Supports a range of packaging specifications for flexible operation

- Employs SCARA robots (OMRON type)

- PLC-controlled with a user-friendly touch screen panel for easy access to settings

- Quick and straightforward product changeover

- Constructed with a heavy-duty stainless steel frame

- Throughput capacity: approximately 40 bottles per minute (BPM)

- Includes safety guard and orientation device

Advantages #

- Accuracy: Advanced vision systems ensure precise bottle orientation and placement.

- Versatility: Handles a wide variety of bottle types and packaging formats.

- Integration: Works seamlessly with other production equipment.

- Adaptability: Easily reconfigurable for new products or requirements.

- Labor Savings: Reduces manual labor, improving operational efficiency.

For more information or to request a quote, please visit the contact page.