Streamlined Bottle Orientation for Automated Production Lines #

Product Overview #

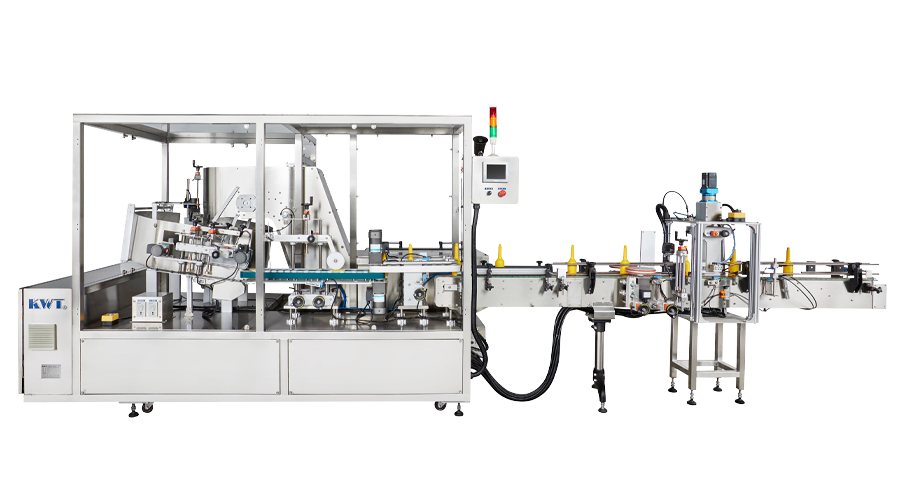

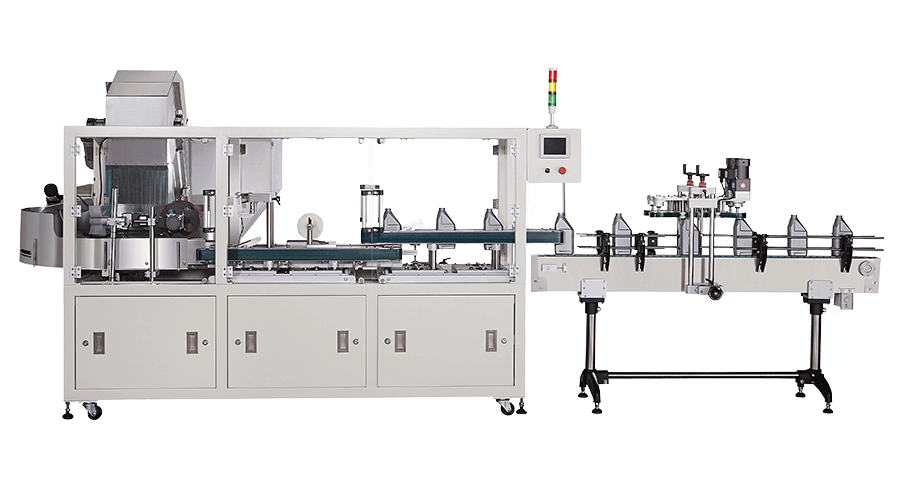

The KWT-101A Linear Bottle Unscrambler is engineered to automate the process of feeding and orienting plastic bottles into production lines. This linear-type unscrambling machine is designed to eliminate manual bottle sorting, offering a labor-saving solution that ensures bottles are consistently and correctly positioned for downstream processes.

Key Features #

- Handles Various Bottle Shapes: Capable of processing cylindrical, square, and rectangular bottles.

- User-Friendly Controls: PLC-controlled with a touch screen panel, providing easy access to all settings.

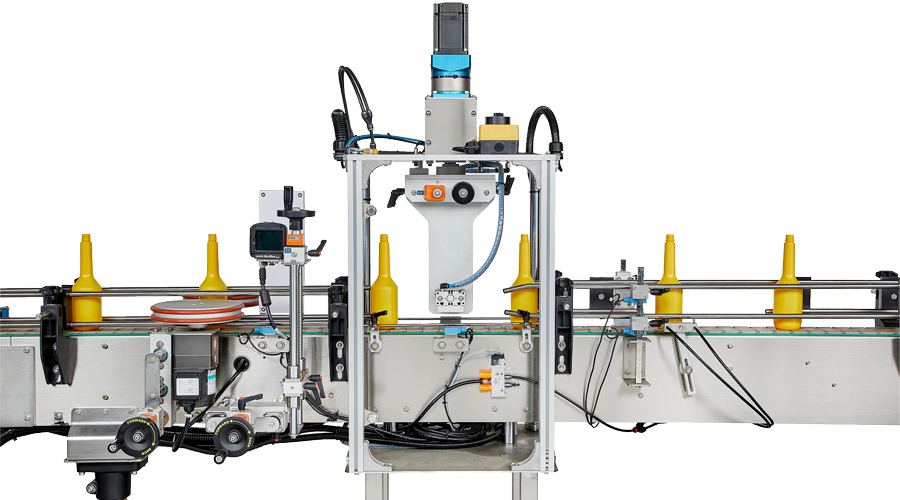

- Quick Changeovers: The hugger belt and hook system allows for fast, easy, and repeatable format changes.

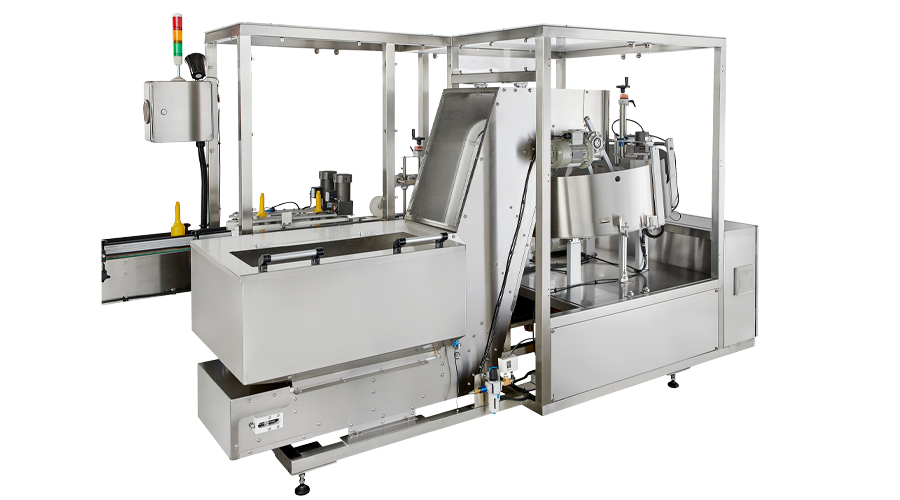

- Durable Construction: All bottle contact parts are made from stainless steel and plastic for longevity and hygiene.

- Operational Simplicity: Designed for straightforward operation, requiring no specialized personnel.

- High-Quality Components: Built with brand-name components for reliability.

- Capacity: Supports speeds of up to 80 bottles per minute (BPM).

How It Works #

Bottles are loaded into a hopper and transported via an elevator to a centrifugal disc. Within the disc, bottles are directed into an orientation area. The Bottle Orientating Hook grabs the neck of each bottle to correct its position. Once upright, bottles are stabilized and released onto the exit conveyor, ready for the next stage of production.

Advantages #

- Increased Efficiency: Automates bottle feeding, significantly boosting throughput and reducing manual labor.

- Improved Productivity: Maintains a consistent flow of bottles, enabling higher production speeds and meeting demanding schedules.

- Versatility: Easily adapts to different bottle shapes and sizes, making it suitable for a wide range of products.

- Seamless Integration: Designed to integrate with other packaging and filling equipment for a smooth production line.

- Cost-Effectiveness: While representing an initial investment, the long-term savings from increased efficiency and reduced labor make it a cost-effective choice.

Flexibility and Adaptability #

The KWT-101A is equipped with numeric counters for all mechanical adjustments, ensuring easy and repeatable changes. Its flexibility allows it to handle new bottle sizes without the need for costly new equipment or major production line reconfiguration.

Industry Applications #

This bottle unscrambler is ideal for industries such as food and beverage, chemicals, household products, and pharmaceuticals, where efficient and reliable bottle orientation is essential.

Additional Resources #

For more information or to request a quote, please contact us.