Induction Sealing Technology for Modern Packaging #

Induction sealing is a critical process in packaging, ensuring product integrity, safety, and extended shelf life. After containers are filled and capped, they undergo induction sealing—a non-contact heating method that welds a foil laminate to the lip of bottles and jars. As containers move along a conveyor, they pass under an induction cap sealer, which performs the sealing operation efficiently and reliably.

Key Benefits of Induction Sealing #

- Tamper-Evident Protection: Induction sealing creates a hermetic seal, preserving product freshness and preventing leaks. The tamper-evident nature of the seal ensures product integrity until it reaches the end consumer.

- Non-Contact Process: The sealing process does not require physical contact between the equipment and the container lid, minimizing contamination risks.

- High Efficiency: Induction sealing is rapid, supporting high-speed production lines. Seals are formed quickly and consistently, boosting production efficiency and reducing downtime.

- Versatility: Suitable for a wide range of container types, sizes, and materials, induction sealing adapts to various cap styles and packaging requirements.

- Extended Shelf Life: Effective sealing prevents spoilage, oxidation, and moisture ingress, helping to extend product shelf life.

KWT has supported numerous lubricant, beverage, food, and dairy packagers in integrating induction sealing into their production lines. Our experienced application specialists are available to help optimize the induction sealing process for your specific products.

Featured Induction Sealing Machines #

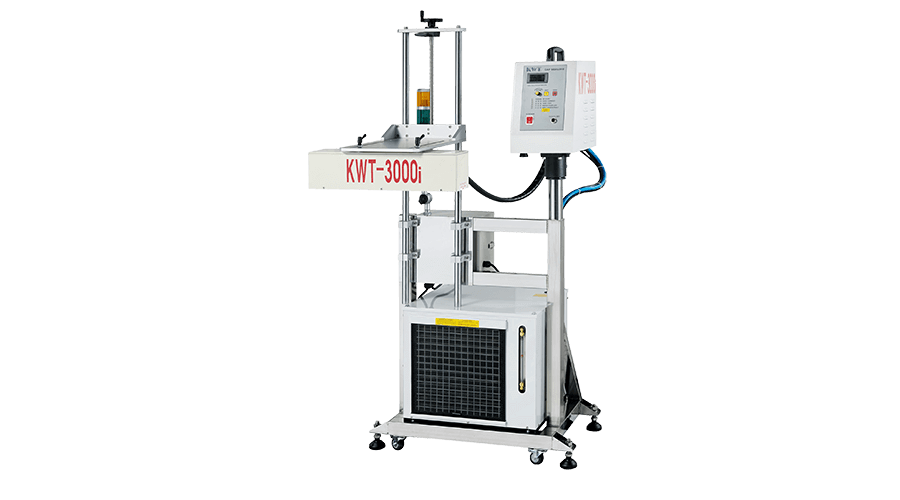

Induction Sealing Machine - KWT-3000i

Induction Sealing Machine - KWT-3000i

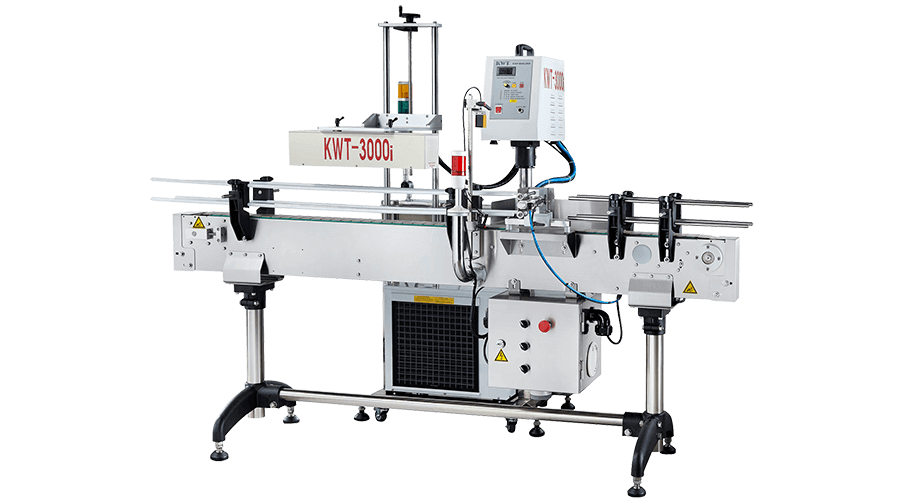

Induction Cap Sealer Machines - KWT-3000ic

Induction Cap Sealer Machines - KWT-3000ic

Automatic Induction Sealing Machines - KWT-500i

Automatic Induction Sealing Machines - KWT-500i

KWT-3000i Water-Cooled Induction Sealing System #

The KWT-3000i is a water-cooled induction sealing system designed for heating foil liners in bottle caps, particularly for plastic bottles. Its modular component design minimizes maintenance requirements, and the system allows for easy adjustment via simple button setup to accommodate different product sizes. The height of the sealing coil is adjustable, making it flexible for most bottle heights. The IGBT/MOS-FET module ensures high efficiency, lower power consumption, and a long lifespan. An optional missing foil detecting sensor and reject system is also available.

Technical Specifications #

| Model No. | KWT-500i | KWT-3000i | KWT-3000ic |

|---|---|---|---|

| Power Output | 500 Watts | 3000 Watts | 3000 Watts |

| Cap Diameter | 20-60 mm | 60-120 mm | 60-120 mm |

| Generator | IGBT | IGBT/MOS-FET | IGBT/MOS-FET |

| Power Supply | 200 V, 50/60 Hz, Single Phase | 200 V, 50/60 Hz, Single Phase | 200 V, 50/60 Hz, Single Phase |

Notable Features #

- Modular design for reduced maintenance

- Simple button setup for product size adjustments

- Adjustable sealing coil height for various bottle heights

- High-efficiency IGBT/MOS-FET module

- Optional missing foil detection and reject system

For more detailed information, refer to the Induction Sealing Machine PDF.

Industries Served #

Induction sealing solutions from KWT are widely used in:

- Chemical

- Food & Beverage

- Household

- Pharmaceutical

For tailored advice and to optimize your packaging line, contact our experienced team at sales@kwt.com.tw or visit our Contact Page.