Automated Solutions for Spouted Pouch Filling and Capping #

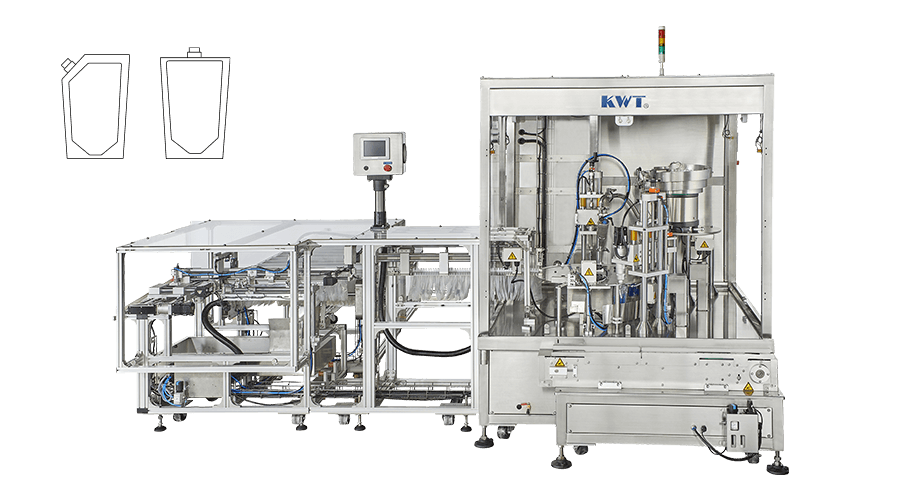

The Pre-Made Spouted Pouch Filling and Capping Machine is engineered to streamline the process of filling and sealing liquid products in pre-made spouted pouches. Designed for both the food and chemical industries, this system ensures efficiency, precision, and reliability in packaging operations.

Product Overview #

This machine automates the process of filling and capping pre-made spouted pouches with liquid products. It is particularly suitable for applications in the food and chemical sectors, offering a reliable and hygienic solution for modern packaging needs.

Key Features #

- Pouch Volume: 100ml to 300ml

- Production Capacity: Up to 40 pouches per minute

- Pouch Dimensions: Width 100mm x Height 165mm

- Construction: Stainless steel for durability and hygiene

- Control System: PLC with touch screen interface

- Pouch Loading: Rail infeed system for efficient loading

- Filling System: Servo-controlled piston pump for accurate dosing

- Capping Mechanism: Servo-driven capping head with adjustable torque via touch screen

- Design: Compact for easy access and maintenance

- Air Consumption: 80L/min

- Power Consumption: 5 kW

Operation Procedure #

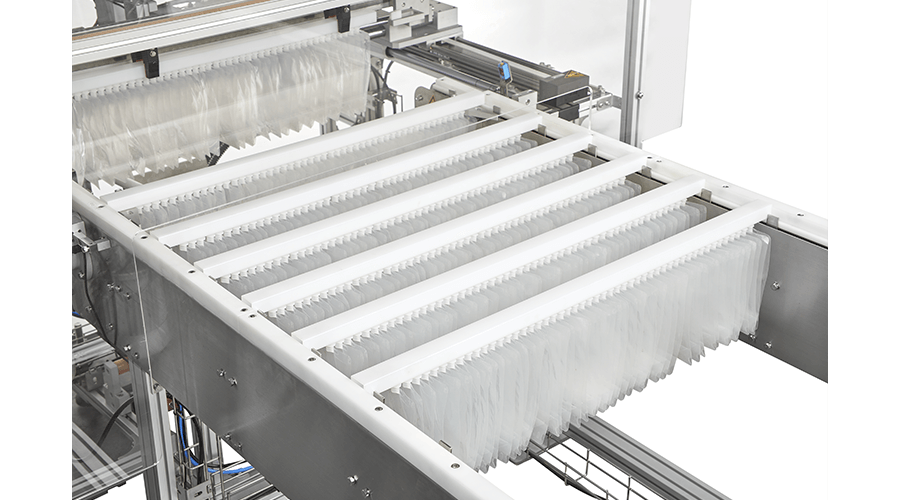

Spout Pouch Infeed #

Multiple rows of pre-made spouted pouches are loaded onto rails. The system transports these pouches into the feeding mechanism, inserting them into a rotary star-wheel for precise positioning.

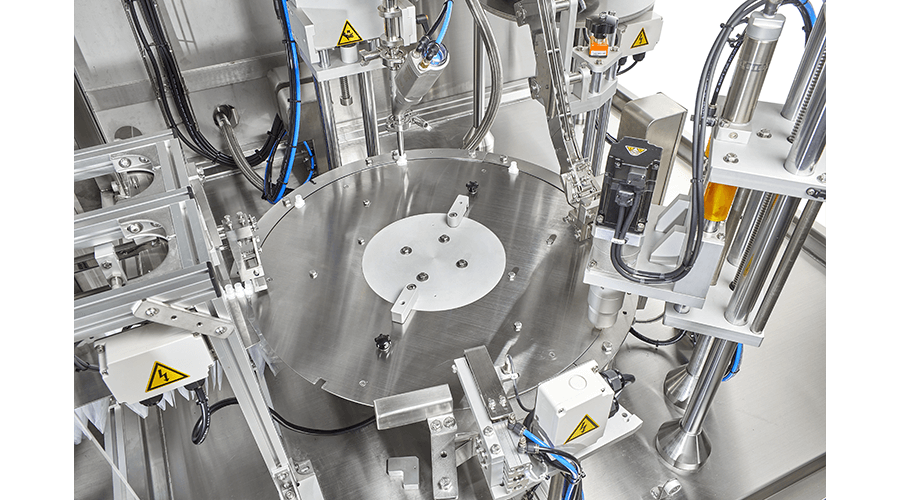

Filling Station #

A filling nozzle is inserted into the neck of each spout, sealing tightly to prevent leakage and ensure pouch expansion during filling. The volumetric piston pump fills one pouch at a time, guaranteeing accuracy and consistency.

Capping Station #

Caps are fed via a vibratory bowl to the cap chute, where they are placed onto the spout. The capping chuck, driven by a servo motor, tightens the caps with adjustable torque, which can be set through the touch screen interface.

Pouch Discharge Station #

After filling and capping, pouches are discharged onto a chute, ready for further processing or packaging.

Additional Resources #

Contact Information #

- Headquarters: No.21, Taiping 21 Street, Taiping Dist., Taichung City 411021, Taiwan

- Tel: +886-4-22773390

- Fax: +886-4-22773412

- Sales & Support Email: sales@kwt.com.tw

- Part & Tech Support Email: service@kwt.com.tw

For more details or to request a quote, please contact us.