Comprehensive Guide to Liquid Filling Solutions for Modern Production #

KWT offers a diverse range of inline filling machines and liquid packaging systems, designed to deliver precision, consistency, and efficiency across multiple industries. Our solutions are engineered to streamline production processes and uphold product integrity, making them suitable for food & beverage, chemical, and household applications.

Key Features of KWT Filling Machines #

- Versatility: Compatible with a wide array of product viscosities and container types.

- High Accuracy & Speed: Engineered for minimal waste and optimal throughput.

- User-Friendly Automation: Intuitive controls ensure seamless operation.

- Compliance: Designed to meet international safety standards.

Product Lineup #

Browse our selection of filling machines to find the ideal match for your production requirements:

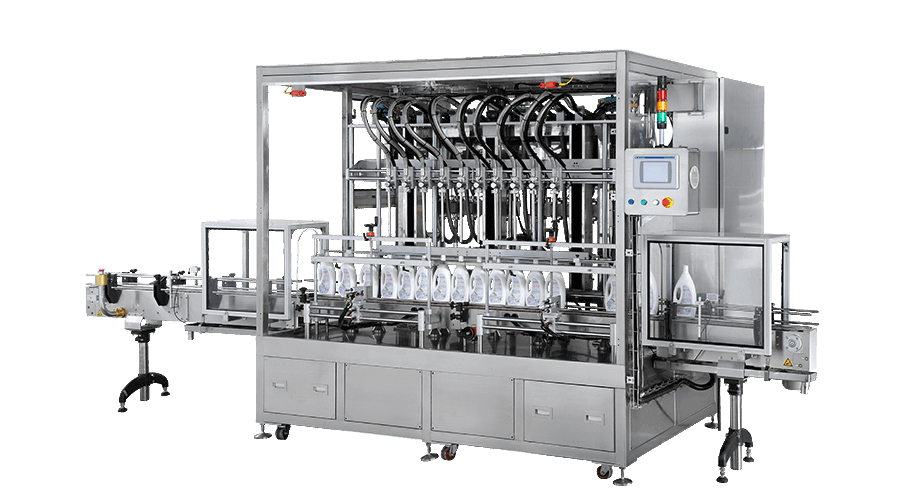

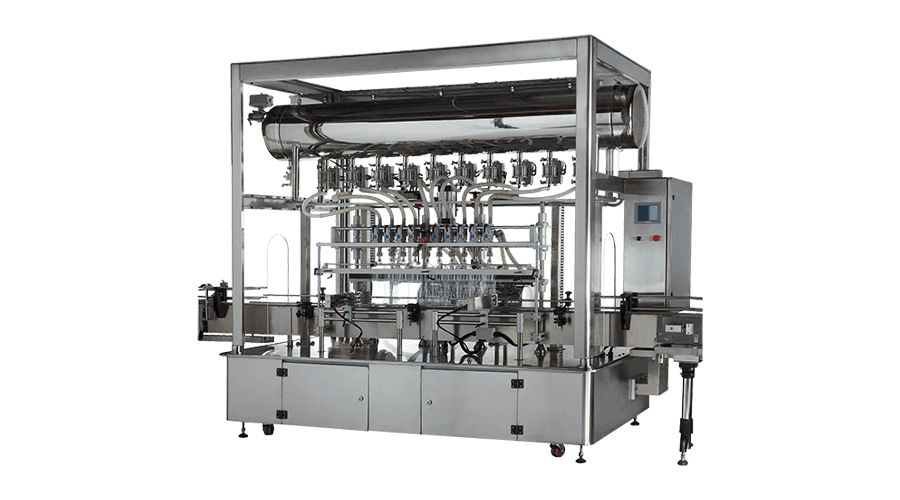

FL Series Auto Volumetric Flow Meter Filler Machine

FL Series Auto Volumetric Flow Meter Filler Machine

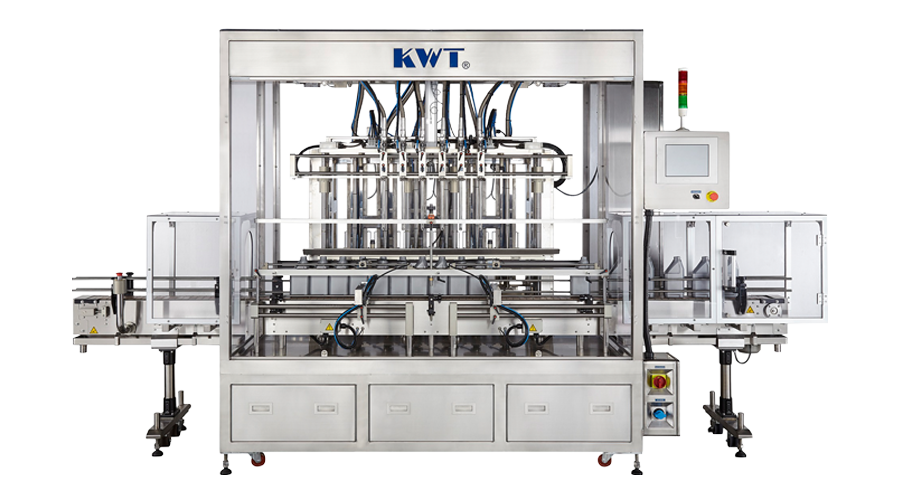

Piston Filling Machine - PS-serials

Piston Filling Machine - PS-serials

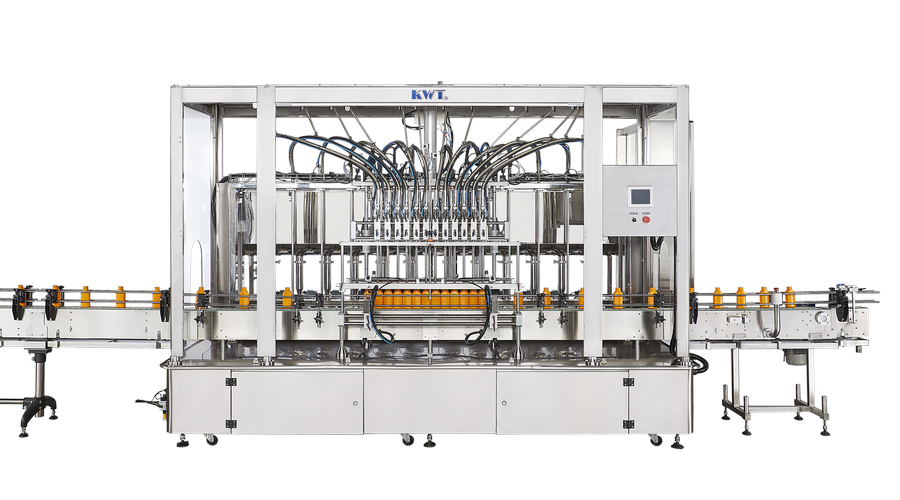

R Series Automatic Rotary Lobe Pump Filler Machines

R Series Automatic Rotary Lobe Pump Filler Machines

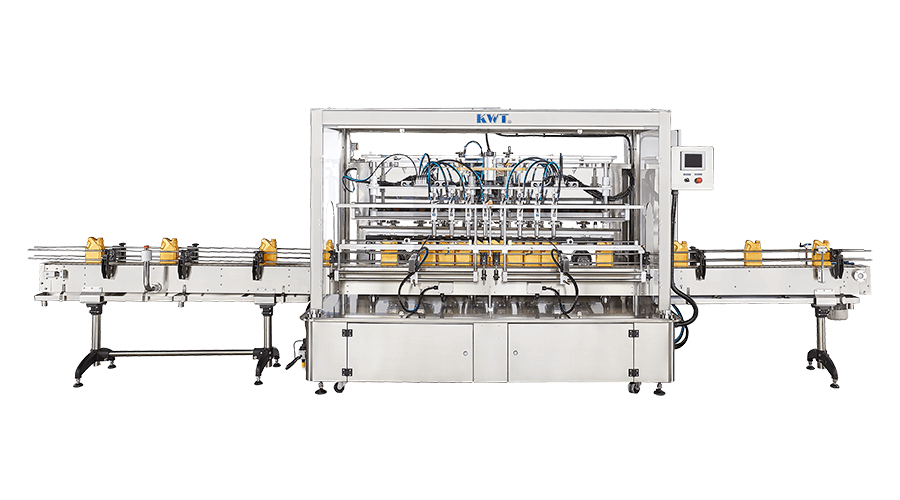

G serials gear pump filling machine

G serials gear pump filling machine

F-Series Overflow Filling Machine

F-Series Overflow Filling Machine

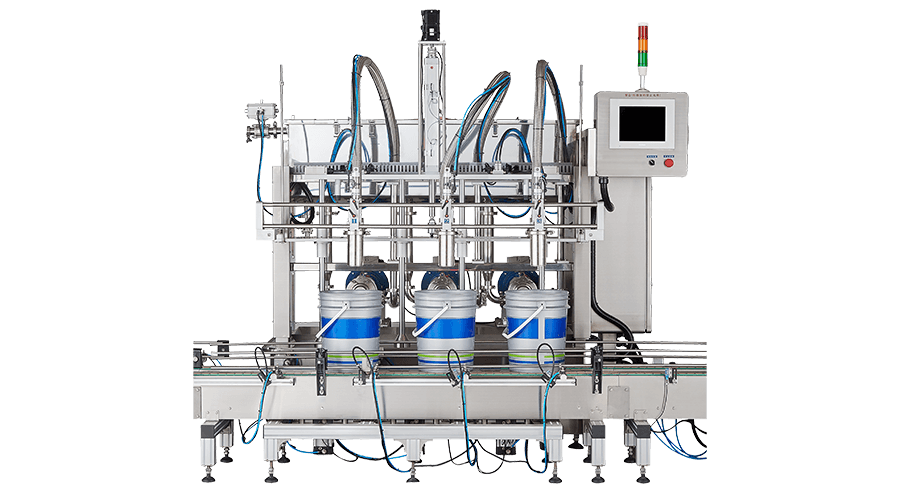

KWT-830W Net Weight Filling Machine

KWT-830W Net Weight Filling Machine

Net Weight Semi-Auto Filler - KWT-820W

Net Weight Semi-Auto Filler - KWT-820W

One Head Semi-Auto Filling Machinery

One Head Semi-Auto Filling Machinery

Product Highlights #

- Flow Meter Filling Machine: Utilizes a measuring principle independent of density, temperature, and viscosity, ensuring accurate dosing. Commonly used for household applications.

- Piston Pump Filling Machine: Delivers precise fill rates and handles a variety of products, including juices, soy milk, sauces, agricultural liquids, and homecare products.

- Rotary Lobe Pump Filling Machine: Each fill head is equipped with a rotary lobe pump and PLC control, allowing for flexible operation across different container sizes and product types.

- Gear Pump Filling Machine: Designed for lubricant oil, adaptable to various container sizes and fill volumes.

- Over-Flow Filling Machine: Ensures consistent fill levels, ideal for transparent containers and thin products such as alcohol.

- Net Weight Filling Machine: Tailored for plastic and metal pail sizes, providing accurate net weight filling.

- Net Weight Semi-Auto Filler: Suitable for filling drums or buckets (10L-20L) with thin to medium viscosity liquids.

- One Head Semi-Auto Filler: Versatile for semi-viscous and thick products, available with single or double pump systems.

Understanding Liquid Filling Machines #

Liquid filling machines are engineered to dispense liquids into containers with precision and efficiency, ensuring uniformity and reducing waste. The process typically involves:

- Container Placement: Empty containers are positioned on the machine, either manually or via automated systems such as bottle unscramblers.

- Filling Assembly: Liquids are dispensed into containers through various mechanisms:

- Volumetric Filling: Measures and dispenses a specific volume using piston pumps.

- Overflow Filling: Maintains consistent fill levels, especially for transparent bottles.

- Container Movement: Filled containers are conveyed to downstream equipment, such as capping or packaging machines.

Key Mechanical Components #

- Hopper: Stores the liquid to be dispensed and signals when refilling is needed.

- Filling Nozzles: Customizable to match container openings for precise dispensing.

- Filling Mechanism: Options include flow meter, piston pump, rotary lobe pump, gear pump, and overflow systems, selected based on liquid properties.

- Conveyor System: Transports containers through the filling and packaging process, with adjustable speed.

- PLC Control System: Touchscreen interface for streamlined operation.

Types of Filling Mechanisms #

- Flow Meter Fillers: Suitable for industrial chemicals and household products.

- Piston Pump Fillers: Ideal for thick pastes, creams, and viscous products.

- Rotary Lobe Pump Fillers: Accommodate a wide range of fill volumes.

- Gear Pump Fillers: Designed for lubricant oil applications.

- Overflow Fillers: Ensure consistent fill levels, especially in clear containers.

Advantages of KWT Inline Filling Systems #

- Adaptable to various liquids and bottle sizes.

- Efficient, cost-effective, and easy to operate.

- Quick product changeover without extensive downtime or costly parts.

- Minimal maintenance and cleaning requirements.

- Seamless integration into existing production lines, with customization options.

- Lower setup costs and easier maintenance compared to monoblock systems.

Industries Served #

KWT filling machines are trusted by manufacturers in:

- Food & Beverage: Juices, sauces, coconut jelly, honey, edible oil.

- Household & Personal Care: Detergent, dish wash, shampoo, shower gel, lotion.

- Chemical: Lubricants, water-based paint, agricultural chemicals.

Selecting the Right Filling Solution #

With decades of experience, KWT is dedicated to delivering reliable and cost-effective filling solutions tailored to your business needs. For more information or to discuss customized options, contact our team for expert guidance.