Ensuring Product Integrity with Advanced Bottle Leak Testers #

Maintaining the highest standards of product quality is essential across industries such as household goods, lubricants, beverages, sauces, and juices. One critical step in this process is bottle leak testing, which helps guarantee that only leak-free containers reach the market. This article delves into the significance of bottle leak testers, their benefits, and the features of KWT’s leak detection solutions.

Why Bottle Leak Testing Matters #

Bottle leak testing is a vital quality control measure that ensures containers are free from defects before packaging and distribution. Implementing a reliable leak detection system offers several key advantages:

- Enhanced Product Safety: Leak testers ensure that only intact bottles proceed to packaging, reducing the risk of contamination and hazards during transport and storage.

- Prevention of Product Recalls: Early identification of leaks prevents faulty bottles from reaching consumers, minimizing the risk of costly recalls and associated financial losses.

- Brand Reputation Protection: Consistently delivering leak-free products helps manufacturers maintain a strong reputation for reliability and quality.

- Reduced Product Loss: By detecting and rejecting defective bottles early, manufacturers can minimize waste and improve overall efficiency.

The Role of Bottle Leak Detectors in Production #

Incorporating a bottle leak detector into the production line is a crucial step that ensures only high-quality, leak-free bottles are distributed. This not only safeguards the end product but also contributes to customer satisfaction and the long-term success of the brand.

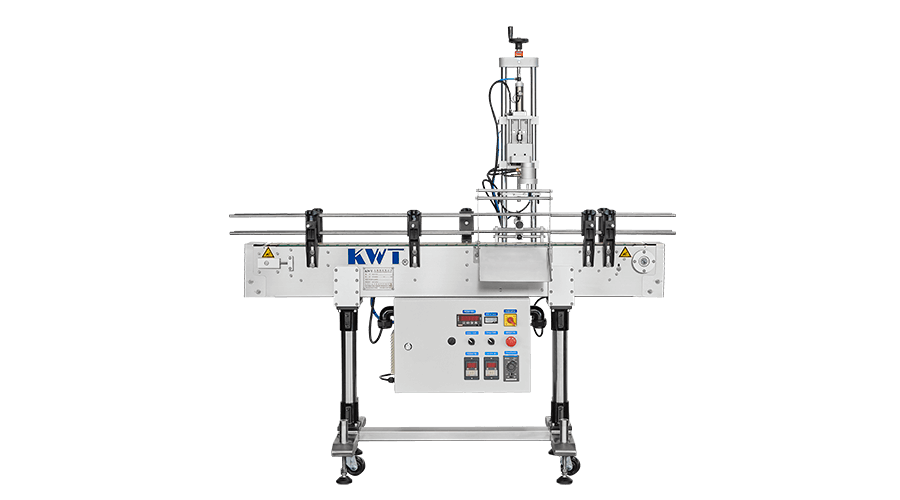

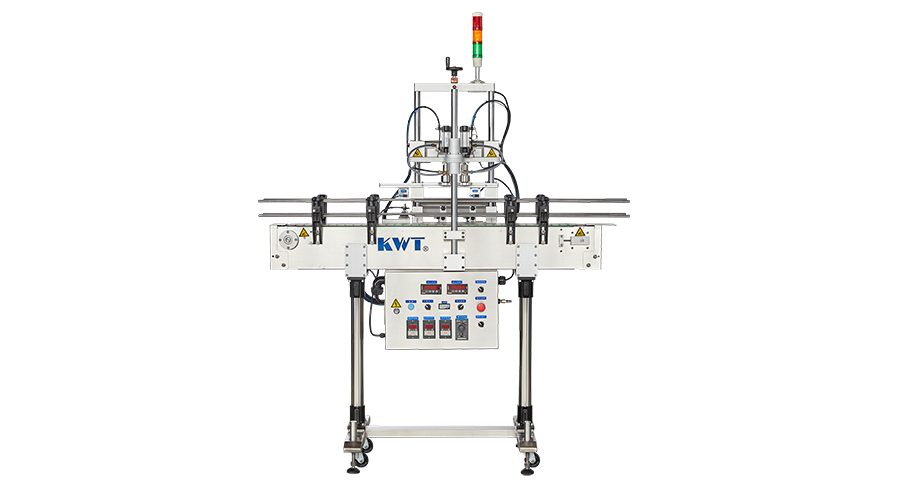

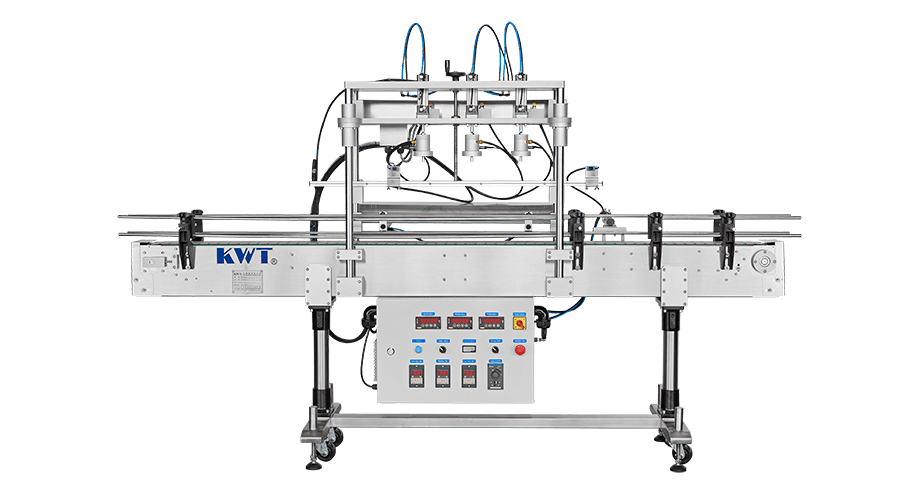

KWT-300 Series Leak Testers: Features and Capabilities #

KWT’s KWT-300 series leak testers are specifically designed for testing empty plastic bottles. These machines are engineered to deliver precise and reliable leak detection, making them an essential addition to any production facility focused on quality assurance.

Key Features:

- Main construction crafted from stainless steel and aluminum alloy for durability

- Mitsubishi PLC control system for efficient operation

- User-friendly setup and maintenance

- Accurate and dependable leak detection circuitry

- Integrated conveyor and rejection station for streamlined workflow

- Capacity: Up to 30 bottles per minute (BPM)

Applications Across Industries #

KWT’s leak testers are suitable for a wide range of applications, including:

- Household products

- Lubricants

- Beverages and juices

- Sauces and condiments

- Pharmaceutical and chemical products

Contact and Support #

For more information or to discuss your specific leak detection requirements, please contact us at sales@kwt.com.tw or call +886-4-22773390. Our team is ready to provide tailored solutions to meet your production needs.

For detailed product specifications, you can also refer to the KWT-310 Leak Tester PDF.